Concrete Blocks vs. Poured Concrete: Understanding the Basics

Concrete Blocks vs. Poured Concrete is a discussion at the heart of construction conversations worldwide—from coastal Belize villages to the high Andes in Ecuador. Whether you’re a builder, traveler, or homeowner, the choice between these two foundational systems shapes the durability, cost, and sustainability of your dream build. Understanding their core differences, especially in diverse climates and terrains, helps you make smart, location-sensitive decisions aligned with your vision and values.

If you’re restoring a home in Costa Rica, launching an off-grid project in Patagonia, or scouting eco-build options in the Scottish Highlands, we’ll break down how concrete blocks and poured concrete differ structurally, economically, and aesthetically—so you choose what works best for your environment and purpose.

Structural Strength and Durability

One of the most critical aspects of choosing between Concrete Blocks vs. Poured Concrete is structural performance, especially in extreme-weather or seismic zones. Poured concrete offers a monolithic structure that’s remarkably resistant to earthquakes, floods, and high winds. In countries within the Pacific Ring of Fire—like Indonesia and Nicaragua—it’s often the top choice for homes, thanks to its seamless strength and reduced weak points.

Concrete blocks can also perform well structurally when reinforced with rebar and quality masonry. In the Dominican Republic and coastal Cuba, traditional block homes have withstood decades of tropical storms. However, joints between blocks can become vulnerable if not sealed properly, impacting long-term durability.

Remote builds in harsh climates—such as Mongolia’s deserts or Patagonia’s windswept plains—often favor poured concrete for its stability. Still, logistics can complicate projects, as it requires formwork, a continuous concrete supply, and skilled labor. Concrete blocks, being modular, are easier to transport and install incrementally, making them effective in off-grid or hard-to-access sites.

Cost and Material Accessibility

Cost is a deciding factor in the Concrete Blocks vs. Poured Concrete debate, especially in rural or developing areas. Across Central America, concrete blocks are affordable and locally sourced, making them popular for self-built homes. In places like Honduras’ Copán Ruinas or Panama’s Herrera province, blocks dominate village architecture because they’re easy to produce, transport, and install.

Poured concrete construction, while strong, usually comes with a higher price tag. It demands formwork systems, a continuous pour process, and tools like mixers or pump trucks—resources that may not be readily accessible in remote regions. Yet in developed zones such as Aspen, Colorado or Queenstown, New Zealand, where batching plants and skilled labor are common, poured concrete becomes a streamlined option, despite its cost.

In remote islands like the Azores or Cape Verde, blocks often win by default. Transporting ready-mix concrete to these isolated areas is cost-prohibitive, making localized block production a more viable and sustainable solution.

Construction Time and Labor Involvement

Time-sensitive projects benefit from understanding how Concrete Blocks vs. Poured Concrete compare in terms of build speed and labor. Poured concrete can drastically reduce construction time, particularly in locations with short build seasons like the Pyrenees or the Rockies. Once poured, walls cure quickly and uniformly, helping speed up final stages.

Concrete block construction is more labor-intensive and slower. Each block is laid, aligned, and mortared individually. In Mayan villages near Lake Petén Itzá in Guatemala, block building traditions create both craftsmanship and jobs—a key factor in places where community building matters as much as the end result.

If you’re volunteering on eco-builds in Nepal during monsoon season or managing unpredictable weather patterns in Laos, the speed of poured concrete may deliver better results. Still, for cultural immersion and employment generation, block building fosters collaboration and long-term local benefit.

Thermal and Moisture Properties

In climates with extreme heat or temperature fluctuations, thermal efficiency significantly influences the Concrete Blocks vs. Poured Concrete conversation. Poured concrete has superior density and offers solid thermal mass, keeping interiors cooler by day and warmer by night. For desert retreats in Joshua Tree or adobe-themed hostels in Oaxaca, this translates to reduced reliance on heating and cooling systems.

However, poured concrete can trap moisture if not properly waterproofed. In humid areas like Thailand’s Chiang Mai or Costa Rica’s Osa Peninsula, concrete blocks allow for better airflow, aiding moisture control. Though less insulating, they can be supplemented with materials like foam panels or natural plasters to offset their thermal shortcomings.

Many builders today combine both methods: using poured concrete for foundations, then erecting block walls to cut costs and improve breathability. This hybrid approach is popular in Peru’s Sacred Valley, where eco-lodges blend concrete with adobe, stone, and sustainable features to balance resilience with comfort.

Design and Aesthetic Flexibility

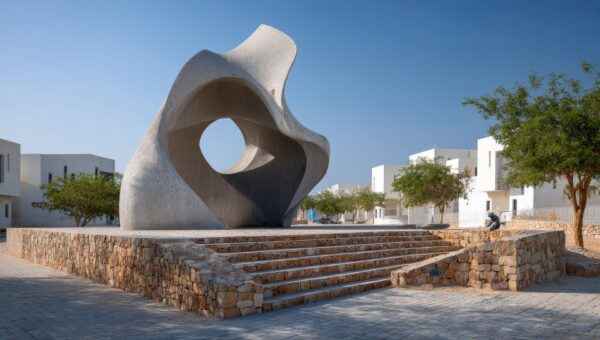

When it comes to architectural expression, Concrete Blocks vs. Poured Concrete each offer unique design possibilities. Poured concrete supports seamless, sculptural forms—ideal for villas in Bali, minimalist cabins in Lapland, or homes that blur natural and built environments, like in Marfa or Ubud.

Concrete blocks, though traditionally functional, have evolved with artisans creating patterns and textures for facades, screens, and shaded spaces. In regions like Morocco’s Atlas Mountains or Andalusian Spain, decorative blocks enhance visual appeal while maintaining structural efficiency.

Hybrid homes on New Zealand’s Waiheke Island showcase poured concrete bases with block walls decorated in stucco, wood, or native vines. This blend delivers both robustness and regional character, striking a balance between modernism and local craft.

Building Codes and Eco-Friendly Practices

Local regulations often determine the outcome of Concrete Blocks vs. Poured Concrete decisions. In flood-prone or high-risk seismic zones like the Florida Keys or Antigua, Guatemala, poured reinforced walls may be mandated by code. Consult a local architect or planner to avoid costly missteps and ensure compliance.

From an environmental standpoint, both materials involve concrete and its high carbon footprint. That said, blocks require less raw material per unit and are often produced locally, reducing emissions related to transport. In areas like the Galápagos or Costa Rica’s Nicoya Peninsula, sustainable builders frequently opt for blocks combined with green roofing or rainwater systems.

Eco-conscious innovators in Puerto Escondido, Mexico, are now producing recycled eco-blocks using volcanic ash and plastic—cutting carbon output while supporting community-led businesses. Meanwhile, emerging materials like reusable formwork and recycled aggregate are making poured concrete more sustainable than before.

Finding the Right Experts and Resources

Choosing between Concrete Blocks vs. Poured Concrete isn’t just about materials, but who builds with them. Local experts play a crucial role in optimizing both techniques for climate, budget, and aesthetic goals. In cities like Oaxaca, Cuzco, or Lanzarote, community workshops offer hands-on training or apprenticeships that empower travelers and residents alike to learn from experienced builders.

In expat hubs such as Medellín, Colombia or Chiang Rai, Thailand, multilingual building consultants can bridge gaps between your design ideas and the local construction reality. Spend time visiting builds in progress, observe techniques, and talk with locals. A conversation at the market could offer as much insight as a site visit.

Ultimately, choosing between concrete blocks and poured concrete is about more than logistics—it’s about connecting with the place, respecting local methods, and building something that lasts. Your walls will shape your shelter, but also your relationship to the land and people that surround you.